July 8, 2023 | 8 min read | By: Parkerville

As experts in lumber, we appreciate the challenges that come with understanding the complexities of wood grain. Beyond that, we also understand the role grain plays in design, construction and ultimately, presentation. Wood grain patterns play a crucial role in the appearance, strength, and suitability of different types of wood for various applications.

In this article, we’ll attempt to explain wood grains in simple terms while also exploring its patterns, types, and practical uses. Whether you’re a woodworking enthusiast or a professional craftsman, gaining a comprehensive understanding of wood grain will empower you to create stunning, durable, and visually appealing woodworking projects.

Wood grain refers to the pattern and arrangement of fibers in the wood. It is a result of the tree’s growth rings, which develop as the tree ages. Wood grain patterns can vary greatly, depending on the species of the tree and the way it is cut. The grain pattern not only affects the appearance of the wood but also influences its strength, stability, and workability. Let’s explore these in more detail:

Strength

The strength of wood refers to its ability to withstand external forces without breaking or deforming. The orientation and arrangement of wood fibers within the grain pattern contribute to its overall strength. Wood with a strong grain pattern can withstand heavy loads and resist bending or breaking under pressure.

Stability

Wood stability relates to its ability to resist changes in shape, size, or structure due to environmental factors such as changes in humidity or temperature. Wood with good stability maintains its dimensions and shape, minimizing the risk of warping, twisting, or splitting over time. Stable wood grain patterns contribute to furniture and structures that remain structurally sound and intact.

Workability

Workability refers to how easily wood can be shaped, cut, joined, and finished during the woodworking process. Different wood grain patterns can affect the ease of working with wood. Some grain patterns may result in smoother cuts and easier shaping, while others may pose challenges such as tear-out or grain direction changes. Understanding the workability of wood grain helps woodworkers select the most suitable types of wood for their specific projects and achieve desired results with precision.

Growth Rings and

Grain Direction

The growth rings in a tree are visible when you cut it horizontally. Each ring represents a year of growth, with the inner rings being younger and the outer rings being older. The grain direction refers to the alignment of the fibers within the wood. The two primary grain directions are “long grain” and “end grain.”

Long Grain

Long grain refers to the fibers that run parallel to the length of the board. This grain direction is the most common and provides strength and stability to the wood. Long grain boards are typically used for structural components, such as table legs, chair frames, and cabinet sides. They are also favored for their visual appeal in applications where the natural beauty of wood is showcased.

Long Grain

End grain refers to the fibers that are exposed when the wood is cut across the growth rings. This grain direction appears as circular or oval patterns on the end of a board. End grain is more porous and absorbs finishes differently than long grain. It is commonly used for applications such as cutting boards and butcher blocks, where its natural hardness and ability to withstand wear and tear are advantageous.

End Grain

Long grain refers to the fibers that run parallel to the length of the board. This grain direction is the most common and provides strength and stability to the wood. Long grain boards are typically used for structural components, such as table legs, chair frames, and cabinet sides. They are also favored for their visual appeal in applications where the natural beauty of wood is showcased.

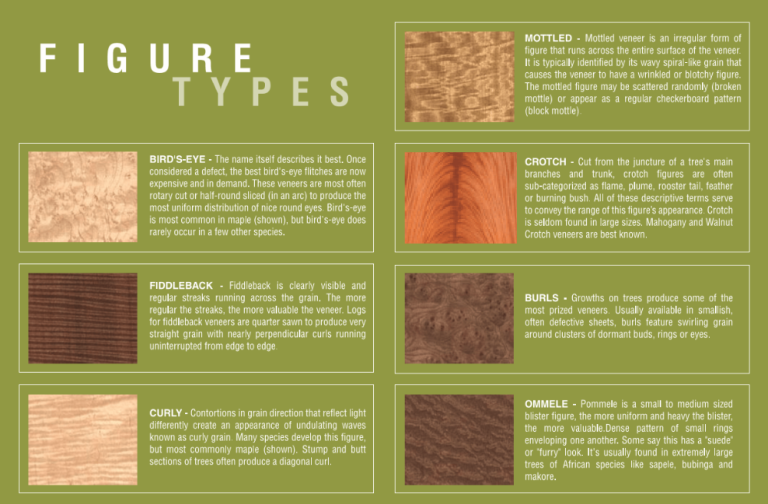

Wood grain patterns can vary greatly depending on the species of wood and the way it is cut. Here are a few of the more well known grain patterns, but there are many more.

Straight Grain

Straight grain is one of the most common grain patterns. As the name suggests, the fibers run parallel to each other in a straight line. This pattern is often found in trees with a single dominant trunk, such as oak and maple. Straight grain provides a clean and uniform appearance, making it ideal for furniture, cabinetry, and flooring.

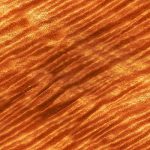

Curly Grain

Curly grain, also known as figured grain, displays a wavy or rippled pattern that appears as if the wood has undulating waves. This pattern is highly prized for its unique and eye-catching aesthetics. Curly grain is commonly found in woods like curly maple and curly cherry. It is often used for accent pieces, musical instruments, and decorative elements that add visual interest to a project.

Bird’s Eye Grain

Bird’s eye grain is a distinctive pattern that resembles tiny swirling dots, giving the appearance of bird’s eyes in the wood. This pattern is caused by irregularities in the growth rings and is commonly found in woods like maple and cherry. Bird’s eye grain adds a touch of elegance and intrigue to furniture, decorative items, and veneers.

Rift Grain

Rift grain exhibits straight and parallel lines running diagonally across the face of the board. This pattern is commonly seen in woods like oak and walnut. Rift grain is created by cutting the log at a slight angle to the growth rings, resulting in a unique and visually appealing pattern. Rift grain is often used in furniture construction, flooring, and cabinetry, adding a sophisticated and modern touch to the finished product.

Tiger Grain

Tiger, curly or figured wood is an aberration that occurs in certain species of wood most notably, maple. This pattern happens on an irregular and unpredictable basis, and turns a basic board into a work of art. The growth of the wood fibers is distorted to produce various types of figure that are independent of the wood grain itself. There are may theories as to what causes this beautiful grain, from genetics, to climate and even the sheer weight of the tree on the supporting trunk.

Since 2005, Parkerville as been importing beautiful, durable and sustainable woods from across the world. Whether you’re a hobbyist who absolutely loves wood, a keen home improver or you’re specifying some timber for a large-scale commercial project, we’re happy to help you achieve your goals. Give us a call!

In celebration of President’s Day, our selection of 4/4 Cherry is on sale! Regular 4/4 Cherry is discounted to $3.99 bf with 8+” wide at $4.49.

Sale runs until February 24th!

** We’re open until 7 PM on Thursdays **