March 1, 2024 | 4 min read | By: David Harris

Greetings Customers & Friends,

Having spent my entire professional life in the woodworking industry, there have been several times that circumstances have taken me to some amazing places. I have always had a curiosity and incentive to explore and search for unique things and businesses when I travel. It usually starts with an internet search for hardwood sellers or woodworking operations that provide products and services similar Parkerville. Today and in the next couple of newsletters, I will share some of the experiences that are forever memorable and, in some cases, helped inspire my career.

One such experience was just prior to me starting my first woodworking business, when I was in the Peace Corps in Ghana. A senior executive for the institute I worked for, the Forest Products Research Institute, took a new job for a company called Mim Timber Co. Ltd., in Mim, Ghana. Once he was settled in, he invited me and another volunteer to visit him for a few days and tour the facility. When we arrived, we stayed in senior guest housing and were treated like royalty. Air conditioning, good food, and cold beer. Rare things for a Peace Corps volunteer.

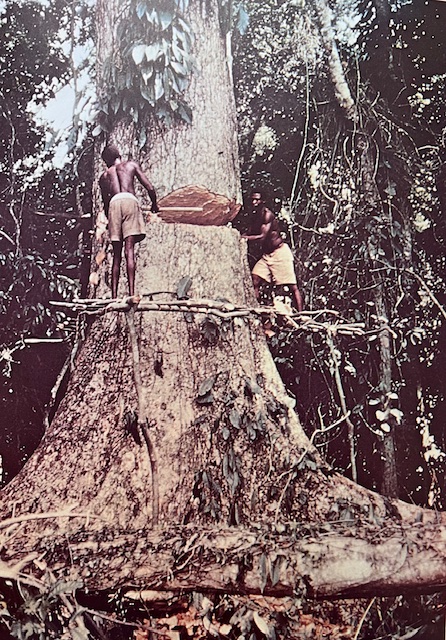

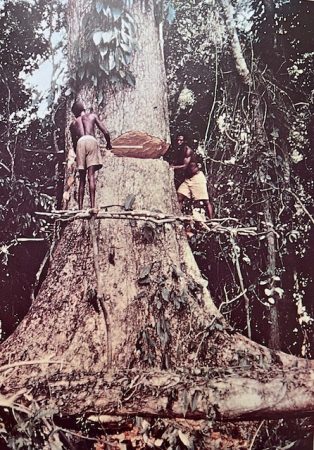

Mim Timber Co. was a giant, state-of-the-art sawmill based in the middle of a giant tropical forest, 50 miles from any other populated area. There was a town, or development there with a population of about 5,000 people. The population lived in mill housing, shopped at the mill stores, and attended the mill schools. Most people had no transportation so living in this remote location was their life. Getting in and out of town was difficult. Transportation out was limited to public busses and private “lorries” which were trucks designed to carry 20 people but would load 30, along with luggage and livestock on the roof. The settlement was probably not unlike what the gold rush in the U.S. must have been like in the mid 1800’s. Typically, the old, poorly maintained logging trucks carried either 1 huge log, which could be 10’ in diameter, or more. Or, if the logs are smaller, they would carry 3 logs, two on the bottom with one on top. Being on the same (dirt) road with them was scary.

When I was there in 1978, the operation had been built and managed by a German company, with an agreement that within a few years the Germans would turn the operation over to local Ghanaian management. It was amazing to see such an ultra-modern, computerized operation in a developing country. Equipment operators in small, air-conditioned glass enclosures moved above the work areas. The operation was on a grand scale. The facility primarily made plywood. Huge logs would be spun and a knife-fed into them so that veneer would peel off the log, appearing like a giant roll of carpet being unrolled. The logs were wet, so water was spraying everywhere. I recall my friend, who worked there as a senior manager, was apprehensive about the long-term future of the operation, particularly after the German company left and the operation turned over to the local management.

In preparation for this column, I searched for current information about Min Timber Co. What I found is unfortunately not all positive. In the late 90’s, the Company was billions of Cedi’s (the local currency – today 1 Cedi = $.07) in debt and was considering closing due to persistent threats from illegal operating within its forest concessions. The culture in many developing countries can make it very difficult for businesses to survive and thrive.

In 2001, the company rebranded and was renamed Ayum Forest Products. Based on what I can find, the company currently employs about 1000 people and today is a multi-faceted company producing a wide variety of wooden products including lumber, plywood, mouldings, sliced and rotary veneers, doors, and furniture of all types. They sell their products all over the world. Although much different from when I was there, the company has survived and appears to be thriving now. Visiting there was an experience that I will remember forever.

Tariff Update – I have read articles in trade magazines indicating the tariffs will be exempt on imported lumber. The challenge, of course, is that what the policy is today may change tomorrow.

We check in with our suppliers on a regular basis and so far, we are not seeing increased pricing due to tariffs. Some Cedar prices have recently spiked but most everything else is pretty stable.

We will continue to keep you informed.

As always, thank you for your business, and I hope to see you at the shop.

Sincerely,

David Harris, President

Parkerville Wood Products, Inc.

Do you need help with a woodworking or wood-related project and don’t know where to turn? We’re here to help. Whether you’re looking for consultation and advice, want help with design options or you’re simply looking for the right selection of wood for your project, we’re more than happy to assist you. Need help when it comes to milling or other services? We can assist you with that as well.

When planning a trip to our facility, please note that you must have proper footwear to enter the shop and lumber mill area. Safety regulations require that open toe shoes or sandals are not to be worn on the shop floor. Thank you for your cooperation.

Parkerville Wood Products

580 Parker Street

Manchester, CT, 06042

When planning a trip to our facility, please note that you must have proper footwear to enter the shop and lumber mill area. Safety regulations require that open toe shoes or sandals are not to be worn on the shop floor. Thank you for your cooperation.

In celebration of President’s Day, our selection of 4/4 Cherry is on sale! Regular 4/4 Cherry is discounted to $3.99 bf with 8+” wide at $4.49.

Sale runs until February 24th!

** We’re open until 7 PM on Thursdays **